Description

[vc_row margin_top=”0″ margin_bottom=”0″ bg_type=”no_bg”][vc_column][vc_column_text]Siemens’ film conveyor weighing solutions are versatile and easily customizable, consisting of three main parts:

1. The weighing system: This is a system with two or more transducers that detect the load on the conveyor belt. The scales are installed under the rolling shutters of the conveyor belt.

2. Speedometer: The speedometer measures the actual speed of the conveyor belt, modifying it as needed to ensure the smoothness of the conveyor belt at all times.

3. Weighing head: The weighing head performs mathematical calculations to make decisions about the flow rate of materials and to calculate the cumulative weight.

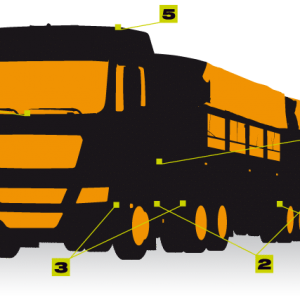

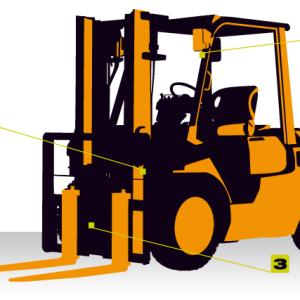

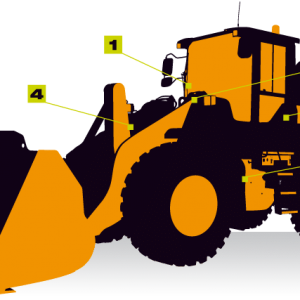

[/vc_column_text][dt_gap height=”20″][vc_column_text css=”.vc_custom_1562151728710{padding-top: 30px !important;padding-bottom: 25px !important;}”]System parts images

[/vc_column_text][vc_row_inner][vc_column_inner width=”1/3″][vc_single_image image=”35603″ img_size=”medium” alignment=”center” style=”vc_box_shadow_3d” onclick=”custom_link” css_animation=”rubberBand” link=”#” css=”.vc_custom_1428840211071{margin-top: 20px !important;}” img_link_large=”yes”][vc_column_text css=”.vc_custom_1562151793970{margin-top: 10px !important;margin-bottom: 10px !important;}”]Weight indicator

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_single_image image=”35766″ img_size=”medium” alignment=”center” style=”vc_box_shadow_3d” onclick=”custom_link” css_animation=”rubberBand” link=”#” css=”.vc_custom_1428841097497{margin-top: 20px !important;}” img_link_large=”yes”][vc_column_text css=”.vc_custom_1562151773268{margin-top: 10px !important;margin-bottom: 20px !important;}”]Conveyor weight

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_single_image image=”35776″ img_size=”medium” alignment=”center” style=”vc_box_shadow_3d” onclick=”custom_link” css_animation=”rubberBand” link=”#” css=”.vc_custom_1428864792301{margin-top: 20px !important;}” img_link_large=”yes”][vc_column_text css=”.vc_custom_1562151761812{margin-top: 10px !important;margin-bottom: 20px !important;}”]speedometer

[/vc_column_text][/vc_column_inner][/vc_row_inner][dt_gap height=”40″][/vc_column][/vc_row][vc_row][vc_column][vc_row_inner][vc_column_inner width=”1/4″][vc_column_text]Advantages

[/vc_column_text][vc_column_text css=”.vc_custom_1566472146297{margin-top: 10px !important;margin-right: 10px !important;margin-bottom: 10px !important;margin-left: 10px !important;}”]Each solution is tailored according to the customer’s needs.

Delivered in partnership with a leading global manufacturer.

Siemens provides specialist industrial knowledge.

Local integration by a leading Israeli supplier.

Unique electronics from the forefront of technology.

Perfect fit for the industrial environment in Israel.

Produced to international standards.

How It Works

[/vc_column_text][vc_column_text]- We start by gathering the information that we need from you, the customer.

- In partnership with Siemens, Shkila identifies and customizes the perfect solution for you from Siemens’ broad product portfolio.

- After your approval, the system is built and sent to Israel.

- Shkila performs the installation (which can be carried out independently according to Siemens’ instructions).

- A weighing technician calibrates the system.

- Initial training is carried out at the client’s site.

Properties

[/vc_column_text][vc_column_text]Systems of different sizes are available (up to 12,000 tons).

Accuracy of 0.125% -1%.

Monitors the flow rate at any moment.

Displays the total weight of material that’s flowed on the conveyor.

Here are our range of Siemens weighing solutions:

[/vc_column_text][vc_tabs interval=”0″][vc_tab title=”MLC” tab_id=”ae7510c2-6f5b-8″][vc_row_inner][vc_column_inner width=”1/4″][vc_single_image image=”35772″][/vc_column_inner][vc_column_inner width=”3/4″][vc_column_text]

| The most common industries we work in: | Food, chemicals and tobacco |

| Main uses: | Process control and process exit for light to medium loads. |

| Accuracy rate: | +/-0.5%-1% |

| Maximum work rate: | 50 tons per hour. |

[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_tab][vc_tab title=”WD600″ tab_id=”1428862092354-2-3″][vc_row_inner][vc_column_inner width=”1/4″][vc_single_image image=”35773″][/vc_column_inner][vc_column_inner width=”3/4″][vc_column_text]

| ענפים עיקריים בהם הוא נפוץ: | מזון, כימיקלים, טבק |

| שימושים עיקריים: | בקרת תהליך, בקרת יציאה מתהליך, תהליכים בקצב קל עד בינוני. |

| דיוק: | +/-0.5%-1% |

| קצב עבודה מירבי: | עד 100 טון בשעה. |

| ענפים עיקריים בהם הוא נפוץ: | מחצבים, חקלאות, מכרות, מתכת |

| שימושים עיקריים: | מסועים ניידים. |

| דיוק: | +/-0.5%-1% |

| קצב עבודה מירבי: | עד 5,000 טון בשעה. |

| ענפים עיקריים בהם הוא נפוץ: | מחצבים, מכרות, מתכת |

| שימושים עיקריים: | מגרסות ניידות, שדרוגי מזינים משקליים. |

| דיוק: | +/-0.5%-1% |

| קצב עבודה מירבי: | עד 2,400 טון בשעה. |

| ענפים עיקריים בהם הוא נפוץ: | צמנט, כימיקלים, פלדה, מחצבים, מזון, מכרות |

| שימושים עיקריים: | שימוש מסיבי בתעשיה, בקרת תהליך ומוצא יצור. |

| דיוק: | 0.5% או טוב יותר |

| קצב עבודה מירבי: | עד 12,000 טון בשעה. |

| ענפים עיקריים בהם הוא נפוץ: | צמנט, כימיקלים, פלדה, מחצבים, מזון, מכרות |

| שימושים עיקריים: | שימוש מסיבי בתעשיה, בקרת תהליך ומוצא יצור. |

| דיוק: | MMI-2 – דיוק של 0.25%. MMI-3 – דיוק של 0.125%. |

| קצב מירבי: | עד 12,000 טון בשעה. |