Description

[vc_row][vc_column width=”1/6″][vc_single_image image=”35693″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Citrine: Software for mixing and mixing materials

[/dt_quote][vc_column_text]Citrin is specialized batching software which allows you to run the entire control system directly from a computer. This smart software program is built in a Windows environment and works as an online system to control resources to achieve the highest manufacturing speed and efficiency possible in the world of industrial dosage and fillers. The software contains an extra layer of security with software screens that are protected through a password protection system.

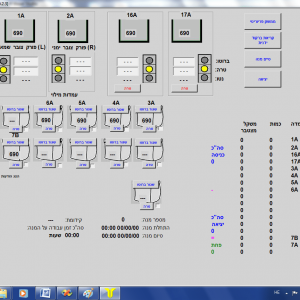

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35689″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Define the raw materials active in the plant

[/dt_quote][vc_column_text]For each plant, you can define which materials are present and which materials are possible. Using this list, you can see what the active material is in each container via the graphic display of the objects on the work screen.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35692″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Link your screen software to your actual factory

[/dt_quote][vc_column_text]The system is built dynamically, which means that the software can be adapted according to the factory it serves. You can add materials and containers, and if there’s a change in the way that the factory is actually connected, you can adjust for those changes on the screen and get a real picture of how the factory looks at any given moment. The software also self-updates.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35691″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]The management and planning process

[/dt_quote][vc_column_text]In this screen, you can define processes and specify how much material to fill, how long the stirrer is in the reception tank and how much time is left between stirs.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35690″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]The screen is intuitive and easy to operate

[/dt_quote][vc_column_text]The screen is designed to be clear and easy to operate. It provides the operator with up-to-date information including the status of taps and cards. This includes what happens in the process at any moment, what’s missing, which tanks are going to be empty, etc

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]The software also contains a bunch of other options and we could never list all of them here. The system also knows how to communicate with external organizational software, to obtain production orders and to report back on what was actually done.

[/vc_column_text][/vc_column][/vc_row]