Description

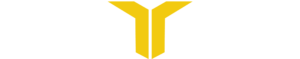

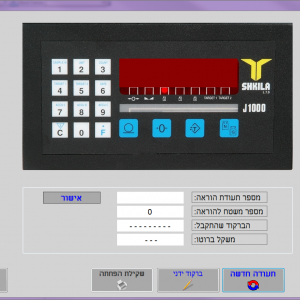

[vc_row][vc_column width=”1/6″][vc_single_image image=”35713″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Topaz: Software for managing batching in concrete plants.

[/dt_quote][vc_column_text]Topaz is the only software of its kind: software that can run a factory without any connection to the controller, instead running the entire control system directly from the computer. Topaz is a smart production software built for Windows 7/Windows 8. The software works as an online system to control resources for the fastest possible manufacturing efficiency and speed in the fast-paced world of industrial dosing and filling. It contains several security layers and all data is protected using a password system.

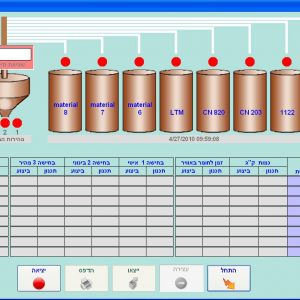

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35718″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Define the raw materials active in the plant

[/dt_quote][vc_column_text]For every plant, you can define which materials are possible and which materials are present at any given time. You can use this list to see what the active material is in each container while viewing a graphic display of your inventory.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35719″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Mix building screen

[/dt_quote][vc_column_text]The mix building screen allows you to define different mixtures from different materials. The ingredients must be in the list of materials, but they don’t have to be from the list of materials that are currently in the specific plant. Each mixture can be defined from a large number of its constituent materials and within the the threshold boundaries of the material.

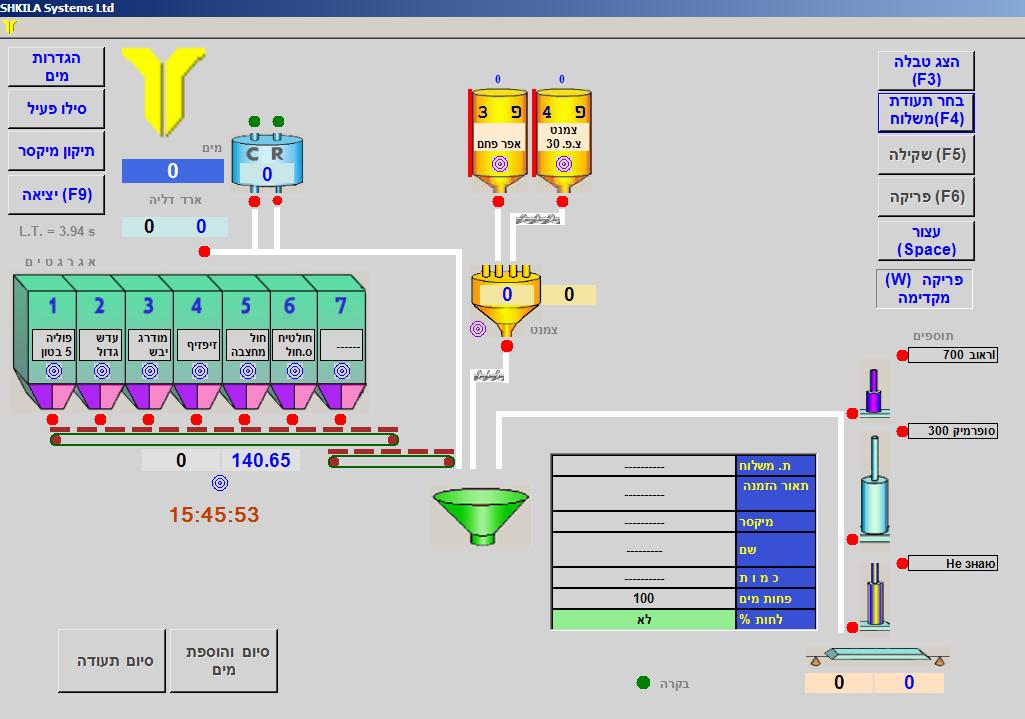

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35716″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Material screen

[/dt_quote][vc_column_text]The system is built dynamically, meaning that it can be changed by the user according to the needs of their factory. You can add materials and containers (e.g. if you add a new material container to a factory that wasn’t there before), download materials and containers, and add or remove different additives. You can view the plant as it is at any moment, all without modifying the software thanks to self-updates. The system won’t allow materials that don’t exist in the plant to be introduced to containers. For smaller changes, such as the transfer of materials between different containers, there’s a “masked materials” screen.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35717″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Material handling system for mixers/trucks

[/dt_quote][vc_column_text]For each mixture, the order of the data can be defined independently. If order is important, enter the order of unloading materials for mixing and update the order as desired.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35714″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]The screen is intuitive and easy to operate

[/dt_quote][vc_column_text]The screen is built in an easy to operate and clear way. The screen provides the operator with access to a range of data, including the status of the taps and the cards. This includes what’s happening in the process at any moment. what’s missing, which tank is about to empty, which snails and pumps work and more. From this screen, you can also switch to various operational settings.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35715″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]A tabular worksheet to display the job status

[/dt_quote][vc_column_text]At any stage during the work, you can go to the central screen and view the data in the execution tables. You can see the status of the process, what’s been done and what needs to be done next. The screen is updated regularly and the whole process is automatically updated online.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]The software contains a whole range of options that are too numerous to list here. It also contains a special module that’s designed for plants. There’s complementary software for the management of work arrangements and for clients to communicate with bookkeeping. The system also knows how to communicate with external organizational software, to obtain production orders from them and to report back on what’s been done.

[/vc_column_text][/vc_column][/vc_row]