Description

[vc_row][vc_column width=”1/6″][vc_single_image image=”35738″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Suglite: Software for monitoring and gathering information in a packing/sorting house.

[/dt_quote][vc_column_text]Suglite enables the managers of packing houses to know what kind of produce they’ve received, what quality it’s in and which batch they came from. The system is also password protected to manage the authorization level of the operator.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35737″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Settings screens

[/dt_quote][vc_column_text]The program has a variety of setup screens in which different parameters can be set. These are specified during installation but can be adapted by customers to suit their changing needs over time. Changeable settings include calibration frequency, markings and warnings for hazardous materials, minimum weights, permissible deviations, exceptional materials and more.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35742″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Screen setting position after sorting

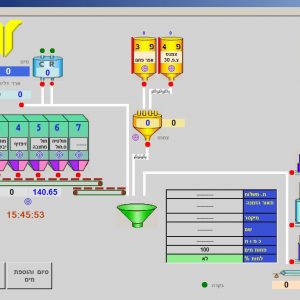

[/dt_quote][vc_column_text]In this screen, you can define what’s filled in the post position (aggregator/container) and other definitions to characterize the fill stage. At the same time, there’s a control to stop the filler in position to avoid overload. When the bag is filled, a sticker is issued so that the operator can tap on the bag for future identification.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35743″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]A data transmission screen for the ERP system (if any).

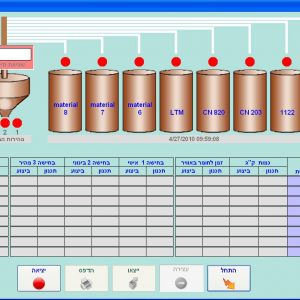

[/dt_quote][vc_column_text]This screen allows the customer to go over the data that should be sent to ERP to make sure it’s in order (to be on the safe side). After checking that everything is normal, the operator can clear the weighing data from the screen.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column width=”1/6″][vc_single_image image=”35734″ css_animation=”rubberBand” img_link_large=”yes”][/vc_column][vc_column width=”5/6″][dt_quote background=”fancy”]Main workspace

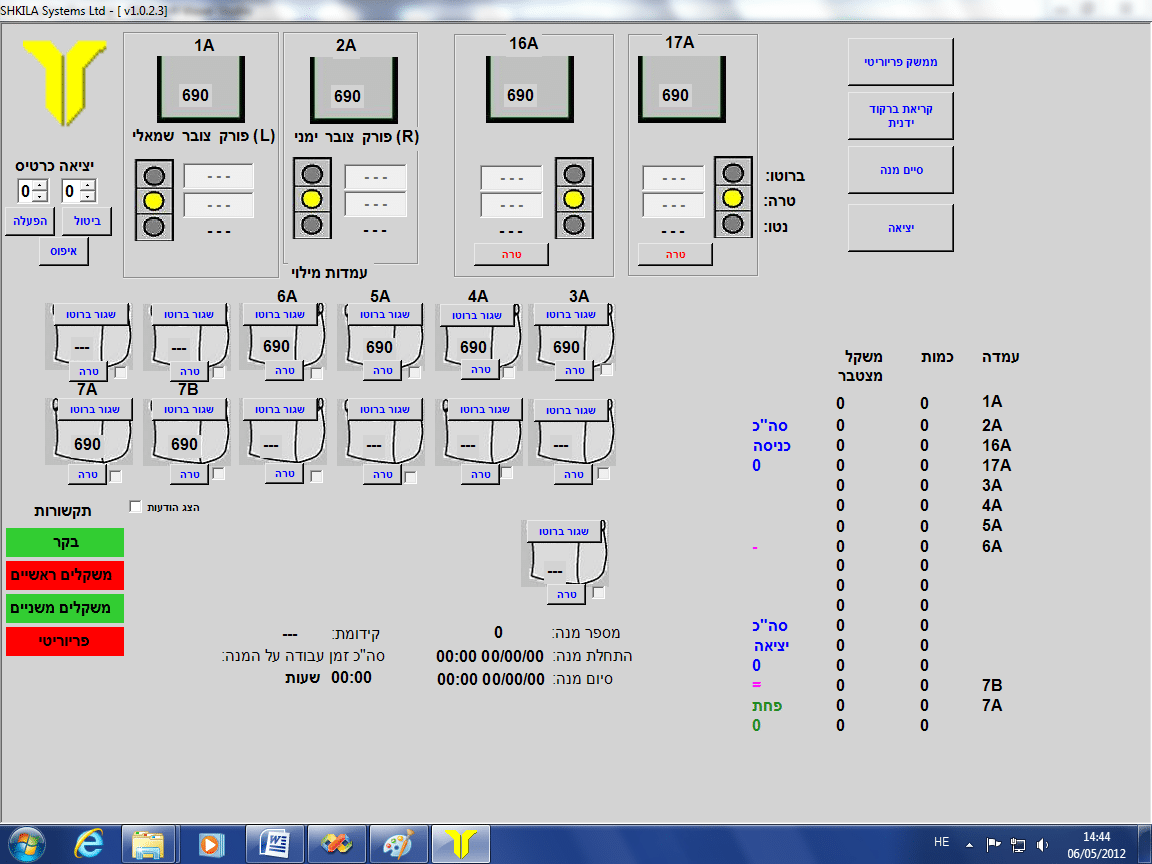

[/dt_quote][vc_column_text]On the main work screen, the operator can see an overview of weighing operations and the condition of all the weights in the entire packing and sorting house. The system enables the management of weights in gondolas, container reversals, hanging huge bags, etc. The system can also recognize the product that’s being considered by reading a barcode or by an operator typing the data manually.

[/vc_column_text][/vc_column][vc_column][dt_gap height=”20″][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]The system is written in an open format that allows the addition and adjustment of data within the software and controls so that you can tailor it to any packing house of any size. We’ll be happy to meet with you and tailor a solution according to your size and needs.

[/vc_column_text][/vc_column][/vc_row]